Description

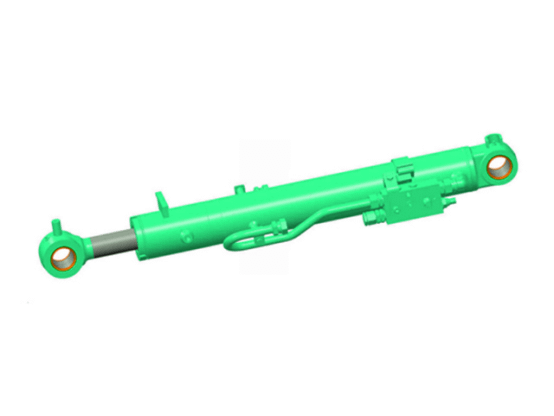

A Hydraulic Cylinder is a fundamental component in hydraulic systems, designed to convert hydraulic energy into linear motion and force. This mechanical device plays a pivotal role in various industries, including construction, manufacturing, transportation, and more, by enabling powerful and controlled movements essential for heavy machinery operations

Key Components

The hydraulic cylinder consists of several critical parts:

- Cylindrical Barrel: The main body that houses the piston and guides its movement.

- Piston: Moves within the barrel, dividing it into two chambers which are filled with hydraulic fluid.

- Piston Rod: Extends from the piston through one end of the cylinder, transferring the generated force to an external load.

- Seals: Prevent fluid leakage and ensure efficient operation.

- Glands: Support and guide the piston rod while containing the seals .

Operation Principle

When pressurized hydraulic fluid is introduced into one side of the cylinder, it pushes against the piston, causing it to move along the axis of the cylinder. This movement translates into linear force, which can be used to perform work such as lifting, pushing, or pulling loads. By controlling the flow and pressure of the hydraulic fluid, precise control over the speed and direction of the piston rod’s movement can be achieved.

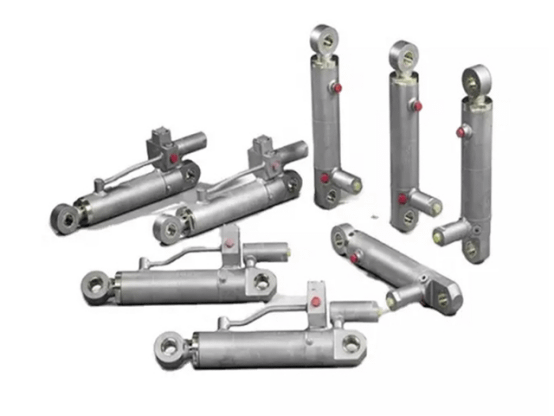

Types and Variations

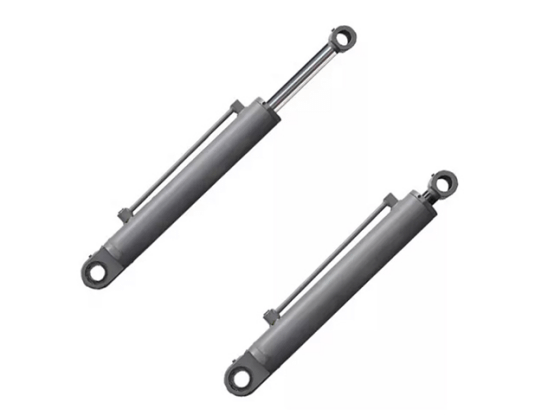

Hydraulic cylinders come in different types tailored to specific applications:

- Single Acting Cylinders (SAC): Utilize hydraulic pressure for movement in one direction only, typically relying on springs or gravity for return.

- Double Acting Cylinders (DAC): Employ hydraulic pressure for both extension and retraction, offering greater versatility.

- Telescopic Cylinders: Feature multiple stages that extend sequentially, providing longer strokes within compact spaces.

- Specialty Cylinders: Include options like oscillating cylinders for angular motion or custom designs for unique requirements

Advantages

- High Force Output: Capable of generating significant forces suitable for demanding applications.

- Smooth Motion Control: Ensures accurate positioning and smooth operation under varying loads.

- Versatile Applications: Adaptable to a wide range of industries and equipment types.

- Durable Construction: Built from robust materials like steel or aluminum, ensuring longevity even under harsh conditions .

Applications

Hydraulic cylinders find extensive use across numerous sectors:

- Construction Equipment: Essential for excavators, bulldozers, cranes, and loaders.

- Manufacturing Machinery: Integral to presses, lifts, and assembly lines.

- Automotive Systems: Used in braking, steering, and suspension mechanisms.

- Agricultural Tools: Found in tractors, harvesters, and material handling devices

Maintenance and Troubleshooting

Proper maintenance is crucial for maintaining optimal performance and extending service life. Regular checks should focus on:

- Ensuring proper lubrication and cleanliness.

- Monitoring seal integrity and replacing worn components.

- Verifying alignment and minimizing misalignment issues.

- Addressing any signs of internal leakage promptly .

In conclusion, hydraulic cylinders represent a cornerstone technology in modern engineering, delivering reliable power transmission solutions across diverse fields. Their ability to transform fluid power into mechanical action makes them indispensable tools for achieving efficiency and precision in industrial operations.